Why a stretch wrapping machine is a strategic investment for logistics

Why a stretch wrapping machine is a strategic investment for logistics

Blog Article

Discover the Advantages of Making Use Of a stretch wrapping machine for Effective Packaging Solutions

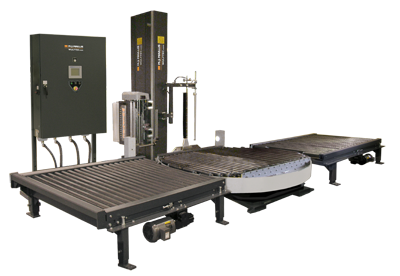

In the globe of packaging options, efficiency is vital. Automation has generated considerable advancements, such as the stretch wrapping machine. With its capability to cover items firmly and quickly utilizing stretchable plastic movie, it offers a high level of accuracy and rate. It's not nearly wrapping products, yet also regarding minimizing labor expenses, lowering waste, and maintaining visual allure. What makes these devices a game-changer in the product packaging industry?

Understanding the Performance of Stretch Covering Machines

Pioneering the packaging sector, stretch wrapping devices simplify the process of securely product packaging items for transportation or storage space. These sophisticated devices use a simple yet efficient device, utilizing a stretchable plastic movie that is wrapped around items, supplying security and defense. The items, commonly arranged on a pallet, are turned as the movie is given, making certain a tight and secure cover.

The movie's elasticity serves a twin objective: it tightly binds the items with each other, reducing the risk of damage because of activity, and it gives a barrier against dust, moisture, and other possible harmful aspects. In addition, the clear nature of the stretch movie permits very easy recognition of the packaged products.

The machines vary in their procedure setting, with some being semi-automatic, calling for marginal human treatment, and others being completely automatic, efficient in individually taking care of the entire wrapping procedure. Despite their setting, stretch wrapping machines are a keystone of safe and efficient product packaging.

Exactly How Stretch Wrapping Machines Enhance Performance

Improving efficiency levels dramatically, stretch wrapping machines simplify the packaging procedure with their automated abilities. These advanced equipments allow firms to cover a high volume of bundles swiftly and efficiently, supplying a constant covering outcome that hand-operated techniques merely can not match. This speed and uniformity translate straight right into boosted productivity, allowing businesses to satisfy requiring supply schedules and consumer expectations.

In addition, stretch wrapping equipments require very little human treatment. Once the maker is set up and the covering specifications are set up, the maker can run independently, liberating workers to focus on other essential jobs. This automation not only decreases labor costs however likewise gets rid of human errors, ensuring the high quality of covering continues to be consistent.

On top of that, the usage of stretch wrapping equipments typically causes less downtime. stretch wrapping machine. With their durable layout and trustworthy operation, these devices are less susceptible to malfunctions and upkeep concerns, ensuring continuous process and improved efficiency

Minimizing Product Waste With Stretch Covering Machines

While improving efficiency, stretch covering makers likewise play a critical duty in lowering product waste. The accuracy of these equipments makes certain that each plan is covered with the specific quantity of product needed, lessening excess waste. This accuracy not only results in an aesthetically pleasing and constant bundle, however also contributes considerably to environmental sustainability.

Essentially, the use of stretch wrapping makers in a packaging line is not just a step towards reliable efficiency, yet likewise a jump in the direction of environment-friendly techniques by dramatically minimizing product waste.

Cost Decrease: A Key Benefit of Stretch Covering Machines

Along with mitigating material waste, another considerable benefit this hyperlink of stretch covering machines is their capacity for cost reduction. These devices are reliable, calling for less manual work for product packaging goods, thus reducing labor prices.

Furthermore, stretch wrapping makers make use of much less material to package products firmly as compared to conventional wrapping techniques. This efficient use of materials not only decreases waste but also lowers expenditure on packaging materials.

The machines additionally decrease damages to items throughout transport. With safe and durable packaging, the risk of product damages declines, lowering the expenses related to item returns and replacements.

Finally, the speed and effectiveness of stretch covering equipments can enhance production prices. Faster product packaging times imply that businesses can package and deliver even more products in less time, boosting total efficiency.

Carrying Out Stretch Wrapping Machines in Your Product Packaging Process

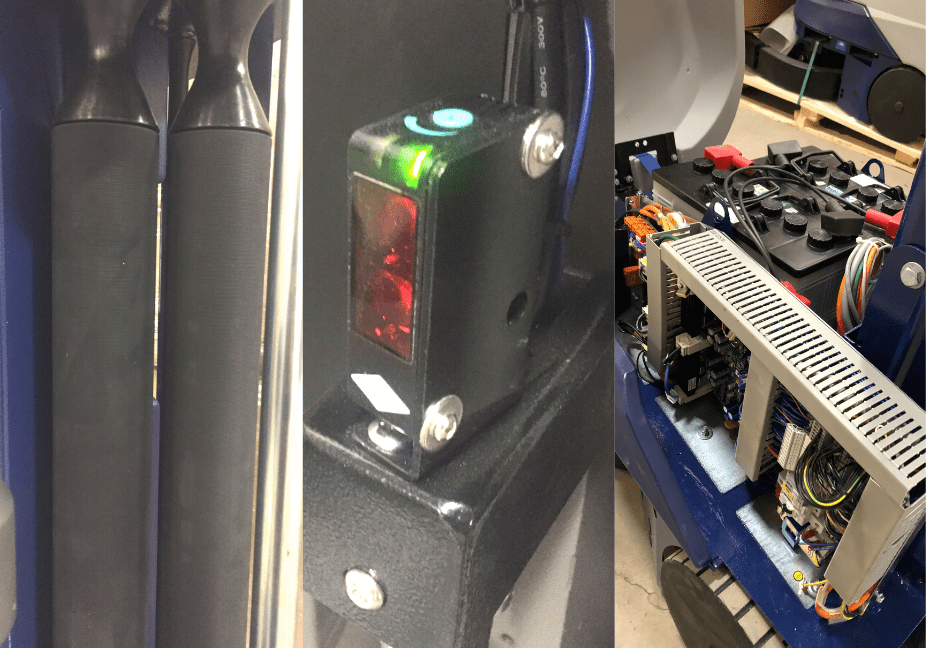

Provided the remarkable benefits of stretch covering devices, including them into your product packaging procedure can be a game-changing decision. An analysis of the current product packaging procedure is needed to identify the ideal maker type and dimension.

Training personnel on device operation is vital. This includes understanding the machine's functionalities, repairing common concerns, and sticking to safety and security standards. By doing so, organizations can make sure a reliable, economical packaging process, official website gaining the complete benefits of their investment in stretch wrapping devices.

Conclusion

In conclusion, stretch wrapping equipments provide reliable, affordable product packaging solutions. These makers make certain product security and defense, while likewise supplying aesthetically pleasing bundles.

Once the maker is established up and the covering criteria are set up, the machine can operate separately, freeing up workers to concentrate on various other essential jobs.While boosting productivity, stretch wrapping machines also play an important function in minimizing product waste.Provided the excellent advantages of stretch covering makers, including them right into your product packaging procedure can be a game-changing decision - stretch wrapping machine. By doing so, services can make sure a reliable, economical product packaging procedure, gaining the full advantages of their financial investment in stretch wrapping equipments

In conclusion, stretch covering makers use reliable, economical packaging solutions.

Report this page